SEL EX

Article Number: 2D: 92.096 215.xxx; 3D: 92.096 389.xxx

- Cast iron housing

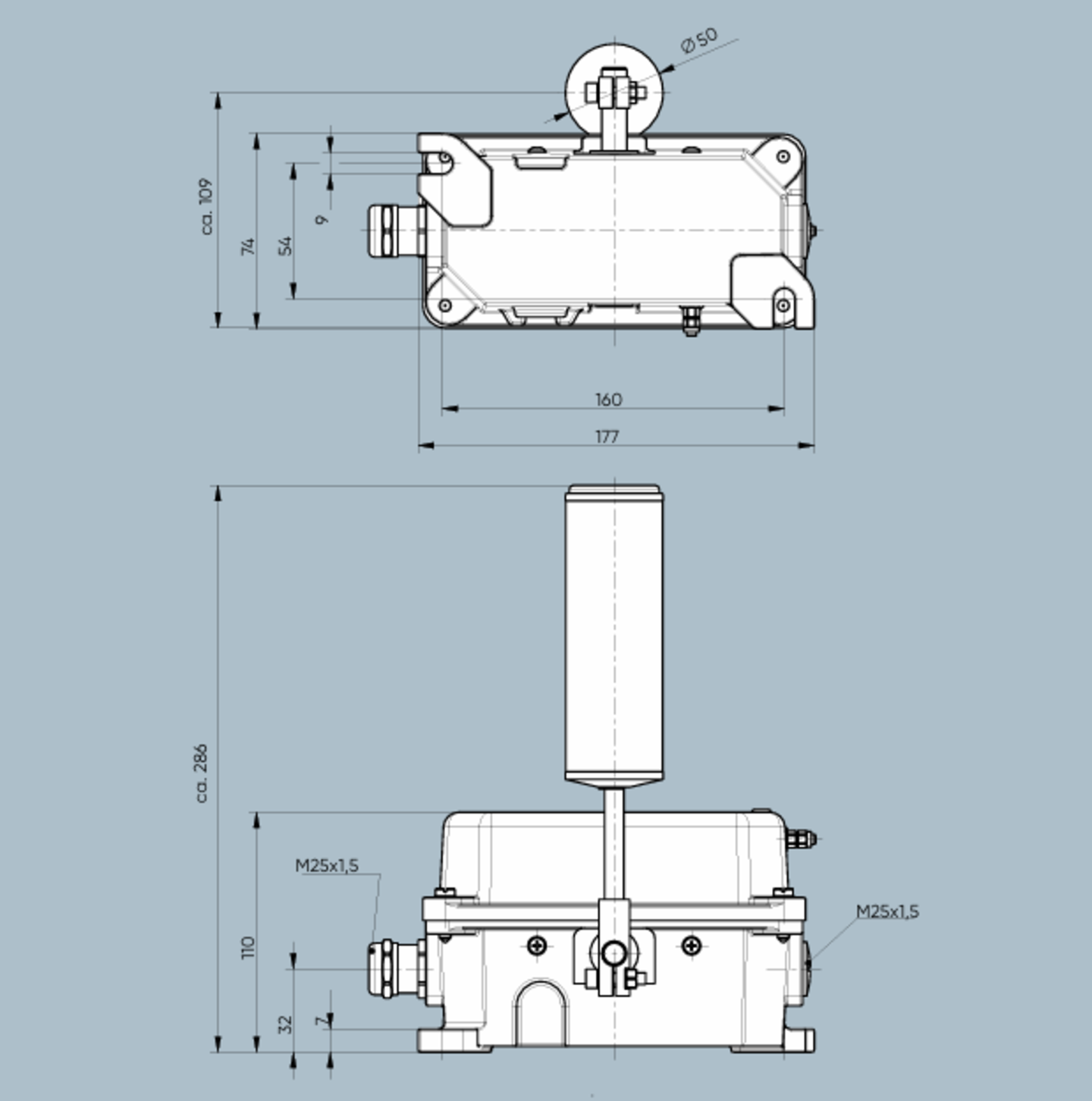

- Stainless steel roller Ø 50 mm

- Adjustable prewarning

- without latching

Features

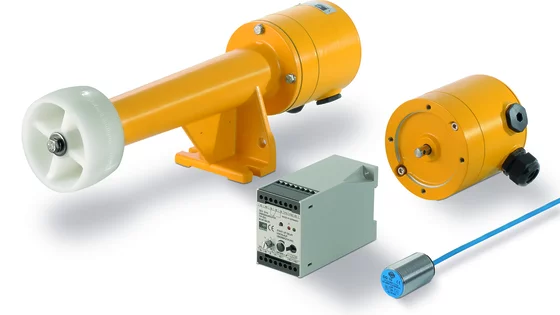

KIEPE belt misalignment switches type SEL EX are used to monitor the misalignment of conveyor belt systems in accordance with the requirements of EN 620. They are used to protect the system from damage or destruction in the event of belt misalignment and are installed in pairs on both sides of the upper or lower run in areas at risk. The ball-bearing roller lever made of alloy steel and with a large roller diameter is resistant to wear that occurs when the moving belt touches the roller.The KIEPE misalignment switches Type SEL EX are suited for use in explosive atmosphere with conductive dust, Group II, category 2 , in zone 21 and 22 (Type SEL EX 2D) or categorie 3, only in zone 22 (Type SEL EX 3D).The Kiepe misalignment switch Type SEL EX complies with the ATEX Directive 2014/34/EU and meets the safety objectives of the Low Vol-tage Directive 2014/35/EU and IECEx.KIEPE Misalignment switch Type SEL EX features a robust cast iron housing and is equipped with up to 4 force-actuated changeover contacts with snap-action function with two settable switching points.

Note: The misalignment switch must only be used in electrical control circuits.

Corrosive

- Powder

- Gravel

- Rubble

Non-Corrosive

- Powder

- Gravel

- Rubble

The misalignment switch type SEL EX switches when the actuating roller is approached and deflected by the misaligned conveyor belt in the direction of rotation of the roller lever. The stainless steel roller lever is mounted on ball bearings, making it better able to absorb lateral forces and impacts. The switching angle can be set for each switching contact using an adjustable roller. In addition to the safety cut-out, this also enables an advance warning to be realized. When the belt is running correctly, the roller lever resets itself automatically.

| Designation | Misalignment Switch Type SEL EX |

|---|---|

| Type of actuation | Bidirectional (double-side) via roller lever |

| Complies with | EN 60947-5-1; EN 60079-31; (EN IEC 60079-0) |

| Suited for | Control units in accordance with DIN EN 60204-1 |

| Device group / device category | II / 2D, 3D; flammable, conductive dust |

|---|---|

| Type of protection | Protection through housing |

| for Zone 21, 22 SEL EX II 2D | II 2D Ex tb IIIC T85°C Db IP67 |

| for Zone 22 SEL EX II 3D | II 3D Ex tc IIIC T85°C Dc IP67 |

| Certificates | EPS 12 ATEX 1 479 X, IECEx EPS 14.0040X |

| Enclosure | Cast iron |

|---|---|

| Coating | PU 2K-paint; Enclosure – yellow (RAL 1004), release lever – red (RAL 3000), reset lever – blue (RAL 5010) |

| Actuating lever | Stainless steel; ∅ 50 mm, ball-beared roller |

| Deflection of roller lever (max.) | +/- 75° |

| Mounting | 2 x M10 |

| Weight | 4.5 kg |

| Switching system (max.) | 4 SPDT (snap action) positive-opening switches |

|---|---|

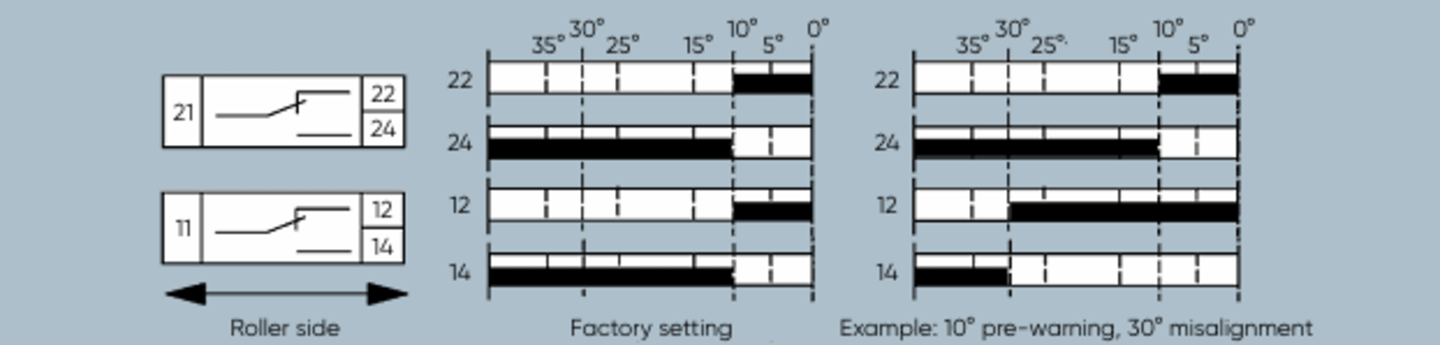

| Switching range | 2x 12,5°, adjustable +/-10° 2x 18°, fix |

| Cable entry (included in scope of delivery) | 2 x M25 x 1,5 with red transport lock 1x screwed cable gland: sealing area ∅ 10 mm to ∅ 17 mm; 1x dummy screw |

| Utilization category | AC-15: 230V ; 1,5A DC-13: 60V; 0,5A DC-13: 24V; 2A |

| Connection cross section (max.) | 2,5 mm2 |

| Protective conductor connection | Protection Class I / protective earthing |

| Potential equalization connection | Enclosure / Cover |

| Rated insulation voltage Ui | 250 V |

| Rated impulse withstand voltage Uimp | 2,5 kV, Overvoltage category II, degree of polution 3 |

| Conventional thermal current Ith | 6A |

| Permissible ambient temperature | –25 °C …+60 °C |

|---|---|

| Protection rating (according to EN 60529) | IP65 / IP67 |

| Contact reliability at AC-15 230V, 1.5 A | >30.000 operations at 100% Ie |

|---|

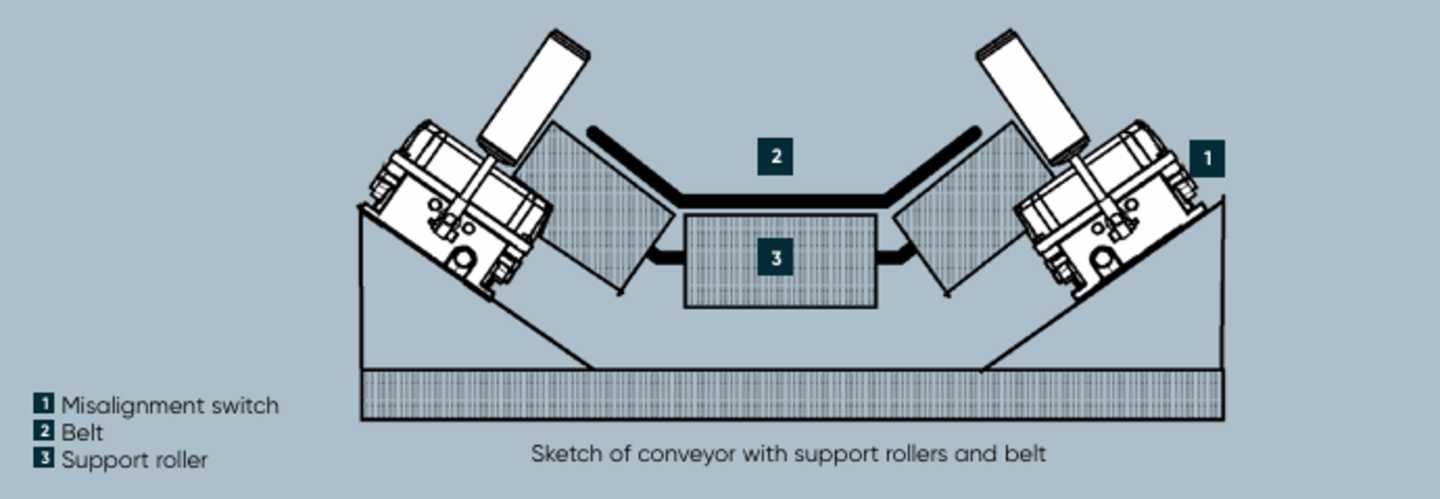

The misalignment switch type SEL EX 1 is fastened to a substructure in the installation position with 2 M10 screws each. In the event of misalignment, the belt 2 must not leave the guide rollers. The actuating roller of the roller lever should preferably be approached vertically by the belt 2 in the event of misalignment. During normal operation, the actuating roller of the misalignment switch is not touched. The roller lever is replaceable and can be variable fixed on the switch axis. The electrical connection is made when the device is open via the cable gland included in the scope of delivery directly to the connection glands of the switching elements.

Note: For protection against electrostatic discharge SEL EX is provided with conductive compounds and external potential equalization connections, to which a minimum of 4 mm2 potential equalization cable must be connected directly to the system. All connections must be checked regularly in accordance with the operation instructions.

Variants

| Name | Ordering No. | Weight | Approvals | ATEX Zone | Contacts NC NO SPDT |

|---|---|---|---|---|---|

| SEL EX 011 2D | 92.096 215.011 | 5.2 kg / 1 Unit | ATEX , IEC Ex | 21 & 22 EX II 2D | 2 (Au) |

| SEL EX 011 3D | 92.096 389.011 | 5.2 kg / 1 Unit | ATEX , IEC Ex | 22 EX II 3D | 2 (Au) |

You have a question? We are here for you!

We are looking forward to hearing from you. We are happy to advise you and help you with the selection of the right product.