EOG

Article Number: 92.099 070.xxx

- Impulsgeber

- Opto-elektronisch

- Alu-Gehäuse

- IP67

Features

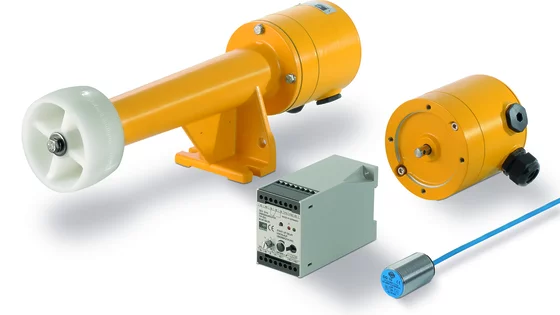

Kiepe pulse transducers of type DK and EOG operate without contact. To make installation easier, the contactless transmisson of the rotary movement into pulses already takes place in these transducers. For this purpose, a pulse disk is permanently mounted on the transducer shaft in the transducer housing. The DK or EOG pulse transducers are connected to the shaft to be monitored via a coupling. The DK /... or EOG /... transducers are always suitable for use where it is not possible to install pulse disks or use other rotating machine parts for pulse transmission. By using these closed pulse transducers, the protective cover required for contact and non-contact pulse transducers can be dispensed with. The pulse sequences can be used for overspeed or underspeed monitoring with the Kiepe speed monitor type EDW. In addition with the Kiepe belt drive B, direct speed monitoring can be achieved on conveyor belts. Reliable slip monitoring thus prevents damage to the conveyor belt. The Kiepe pulse transducer type EOG and DK complies with the Low Voltage Directive 2014/35/EU and EMC Directive 2014/30/EU.

Note The use of shielded cables is recommended for joint installation with control or power cables.

Corrosive

- Powder

- Conditionally Suitable

- Gravel

- Conditionally Suitable

- Rubble

- Not Suitable

Non-Corrosive

- Powder

- Suitable

- Gravel

- Suitable

- Rubble

- Not Suitable

The opto-electronic EOG is powered by the external speed monitor. This pulse transducer generates voltage pulses with extremely steep switch-on and switch-off edges. Due to the high dimensional accuracy of the built-in pulse disks, the exact pulse spacing is guaranteed even at a pulse rate of 25 pulses/ rev. Due to the pulse multiplication of max. 25 pulses/rev, these pulse transducers are suitable for monitoring the standstill of drives in addition with Kiepe speed monitor EDW. Variants of type EOG are available with 1, 5, 10 or 25 pulses/rev.

| Designation | Speed monitoring - pulse transducer type DK & type EOG |

|---|---|

| Protection rating | IP67 |

| Connection cross section (max.) | 2,5 mm2 |

| Mounting | 4 x M6 / L <12 mm |

| Weight | 1,5 kg |

| Permissible ambient temperature | -25°C...+70°C |

| Functionality | opto-electronic |

|---|---|

| Complies with | EN 50178, EN IEC 61000-6-2, EN 61000-6-3 |

| Switching system | PNP and NPN |

| Pulse disk Imp./U. | 1,5,10,25 |

| Rated operating voltage Ub | DC 24 V |

| Rated voltage | - |

Current consumption activated Current consumption unactuated | - |

| Rated insulation voltage Ui | DC 250 V |

| Switching output | PNP/NPN |

| Switching frequency (max.) | 0,4 kHz |

| Connection | 3-/4-wire |

| Connection drawing | A |

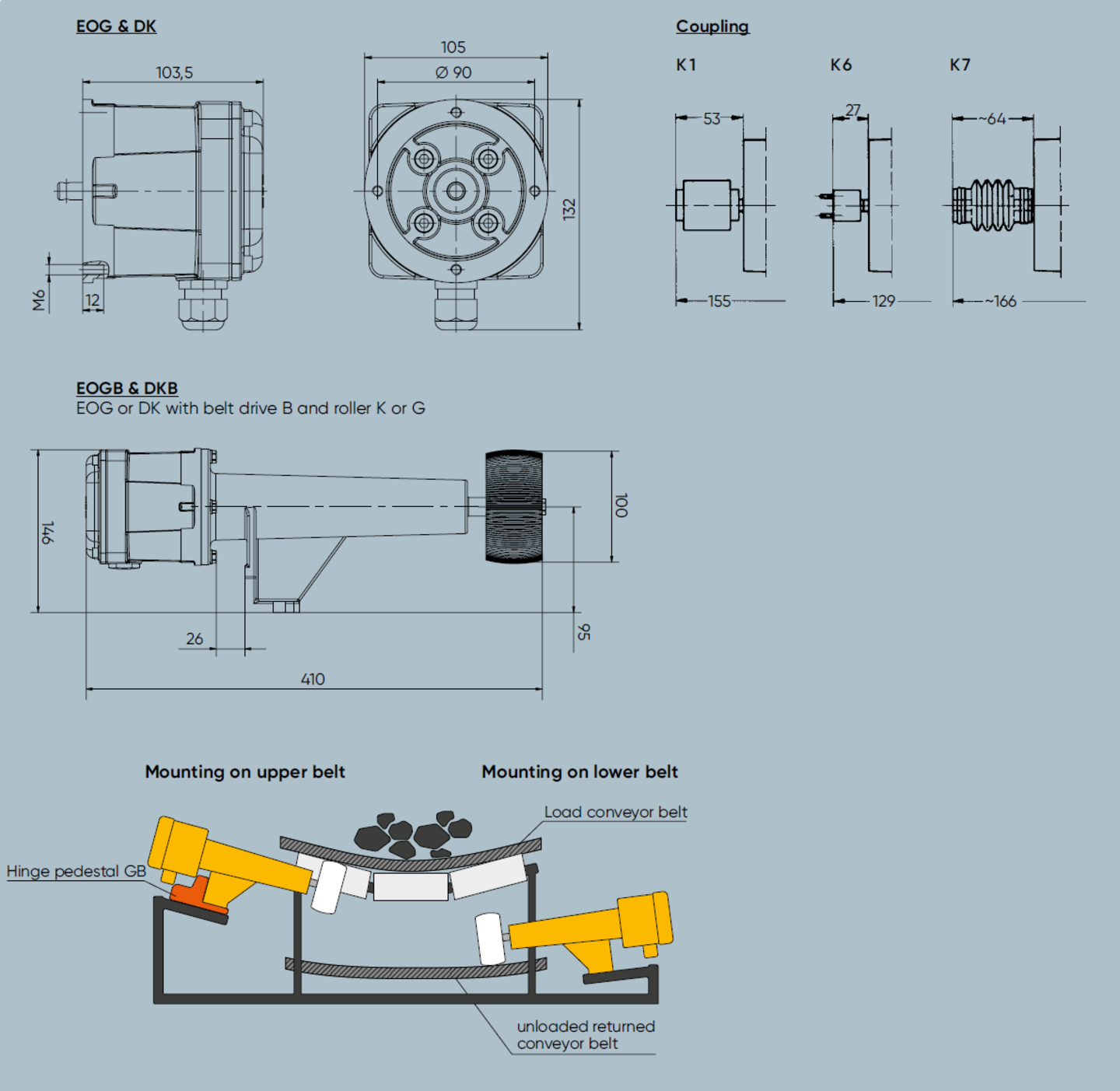

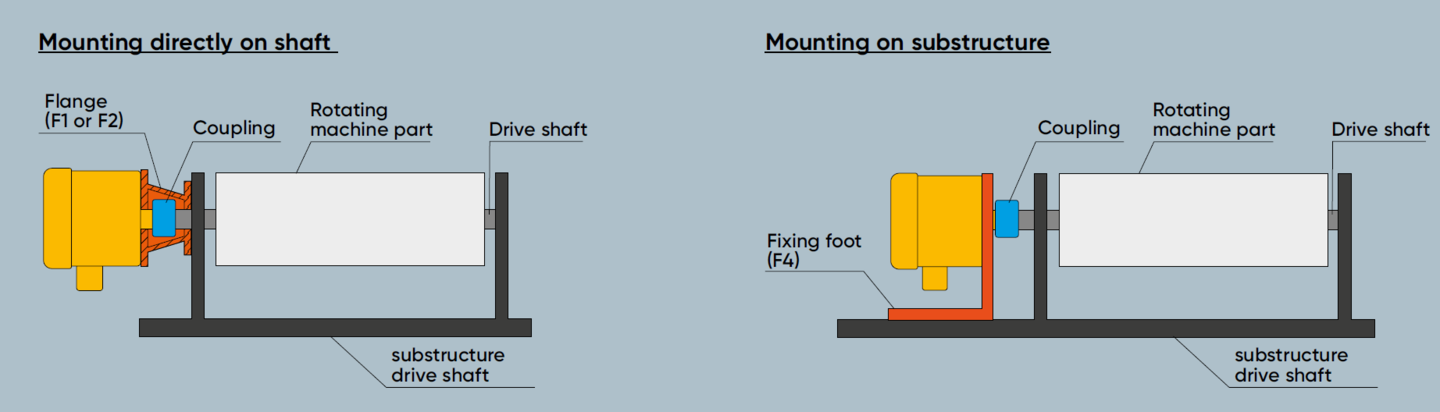

Pulse transducer type EOG and DK are attached to the substructure of the monitored machine using 4 M6 screws each. This is done using flange (F1, F2) or fixing foot F4. The connection to the rotating shaft is made using couplings (K1, K6, K7) depending on the EOG or DK shaft version. When the speed is taken directly from the belt, the EOG or DK is attached to the belt drive B. The belt drive is pressed against the cleaned side of the belt using a hinge pedestal GB. The electrical connection is made when the device is open via the cable gland included in the scope of delivery directly to the accessible connection screws.

Note When using the belt drive B, make sure that the belt load cannot damage the EOG or DK. With direct connection using fasteners care must be taken to ensure that the EOG or DK can resonate with the rotating part of the machine. (See mounting drawing)

Variants

| Name | Ordering No. | Weight | Impulse / Revolution | Execution DC | Shaft |

|---|---|---|---|---|---|

| EOG 001-2 S | 92.099 070.010 | 1.1 kg / 1 Unit | 1 Imp./Rev. | 24 V | Round 10 mm |

| EOG 005-2 S | 92.099 070.001 | 1.1 kg / 1 Unit | 5 Imp./Rev. | 24 V | Round 10 mm |

| EOG 010-2 S | 92.099 070.004 | 1.1 kg / 1 Unit | 10 Imp./Rev. | 24 V | Round 10 mm |

| EOG 025-2 S | 92.099 070.007 | 1.1 kg / 1 Unit | 25 Imp./Rev. | 24 V | Round 10 mm |

You have a question? We are here for you!

We are looking forward to hearing from you. We are happy to advise you and help you with the selection of the right product.